Contents

Background

The idea of the Water Transportation Project is to cooperate with Norwegian government departements, to facilitate transport of water as part of foreign aid, with use of their technology. The background is the Norwegian Water Initative

Included companies

The Water Transportation Project LLC (hierin after WTP) is an Armenian Company with Reg. No. 02673107. The company is politically neutral and deals with buying, selling and transportation of sweet water in bulk.

Norden-Water AS (hierin after N-W) is a Norwegian Company with Reg. No. 924 588 241. The company deals with buying, collecting and selling high quality drinking water to end users or to bottling plants in the end users’ area.

The two companies have established a close cooperation, based on supply of the same product (sweet water), customer service through the same channels and a common management.

Deliveries to customers

N-W is supplying spring water of high drinking quality, bottled in cardboard boxes of different sizes, so far basically 0,5 litres for delivery to end users. In Norway the majority of these deliveries happen through the country’s largest distributor.

N-W also offers the option of bulk delivery in 20 feet containers, loading approx 24 tons of high quality drinking water meant for bottling plants in the end users’ area.

WTP offers bulk supply of sweet water in large quantities, i.e. Suezmax tanker ships loads of sweet water for delivery to the customers’ water distribution net and tanks in order to replace as much as possible of the desalinated water sent into distribution nets in arid areas. These supplies will have a great impact on the environment, and on the customers’ economy as well.

WTP also offers bulk delivery of refined sweet water. in 20 feet containers.

Means of transportation

High quality drinking water in 0,5 litres cardboard boxes from N-W are being packed in so called D-packs (2 x 6 units) and put onto pallets to be wrapped in plastic film. The pallets are loaded into standard containers for transportation by truck, railway and/or container ships.

High quality bulk water from N-W is being filled into 20 feet containers. This is a “bag in box” system, since the containers are inside equipped with a single use plastic bag. Upon delivery to customers, the plastic bag will be ripped out of the empty container and removed from further use. The service is supplied by the Danish forwarding company Hillebrand.

WTP as well offers the same type “bag in box” delivery of refined sweet water.

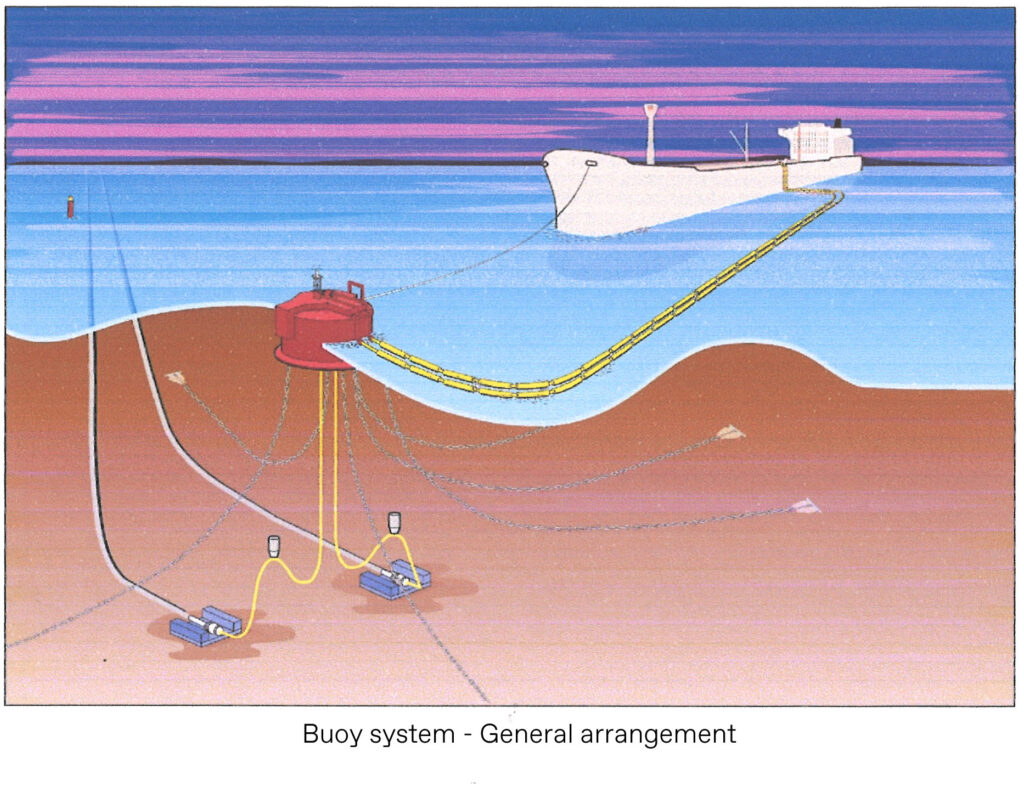

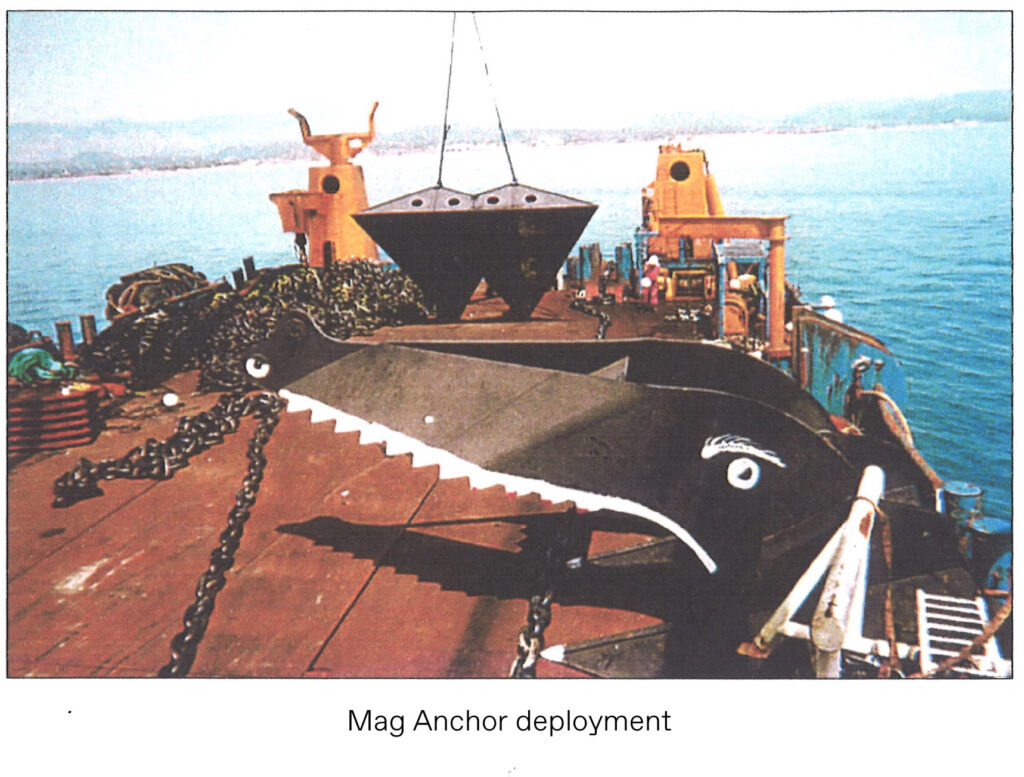

WTP’s large quantities of sweet water to be supplied will happen on board tanker ships, which for obvious reasons have to be of size Suezmax. The idea is to charter a second hand oil tanker and have it serviced and modified. The modifications will include replacement of all pipes, valves and pumps, since proper cleaning for water transportation will not be possible.

Two main pipes of Ø = 1 400 mm are to be installed in center of the ship’s deck full length. To each tank there will be a connecting pipe to a submercible bilge pump for loading or unloading of the tanker ship within 10 hours. All tanks to be coated with an environmentally acceptable coating, approved for foodstuffs. Loading and unloading of the tanker ship to follow recommendations from MARINTEK, part of the Norwegian University of Science and Technology

Sweet water sources

N-W has access to bed rock water from springs in the Norwegian mountain areas. Collecting pipes, tanks and distribution net from two springs are already in operation. Included are also valves, gauge and fittings installed in a site that is well accessably by truck for transportation to customers by the “bag in box” container system.

The water quality has been tested, and it was well accepted by the Saudi Arabian Ambassador and his wife during a visit to the site towards the end of their service period in Norway. An exclusive MoU relating to the sweet water supply to Saudi Arabia was then immediately signed.

Upon their ended service period in Norway, the ambassador and his wife were to return to Saudi Arabia, where she would manage her own company, providing and distributing sweet water to cusomers in Saudi Arabia, whereas he would take up a position as governmental purchasing manager of imported goods, like water.

For the time being N-W is supplying drinking water in cardboard boxes from a bottling plant on top of a spring water source of excellent quality 100 meters below earth surface. The idea is to put up a new bottling plant for bed rock water in the Norwegian mountain area.

WTP offers bulk deliveries of refined sweet water according to the “bag in box” container system, or Suezmax ships loads as mentioned under “Means of Transportation” above.

The source is a good size sweet water collecting system, and a refining and loading plant as well in Manavgat, Turkey, that was designed, erected and commissioned in the 1990ies.

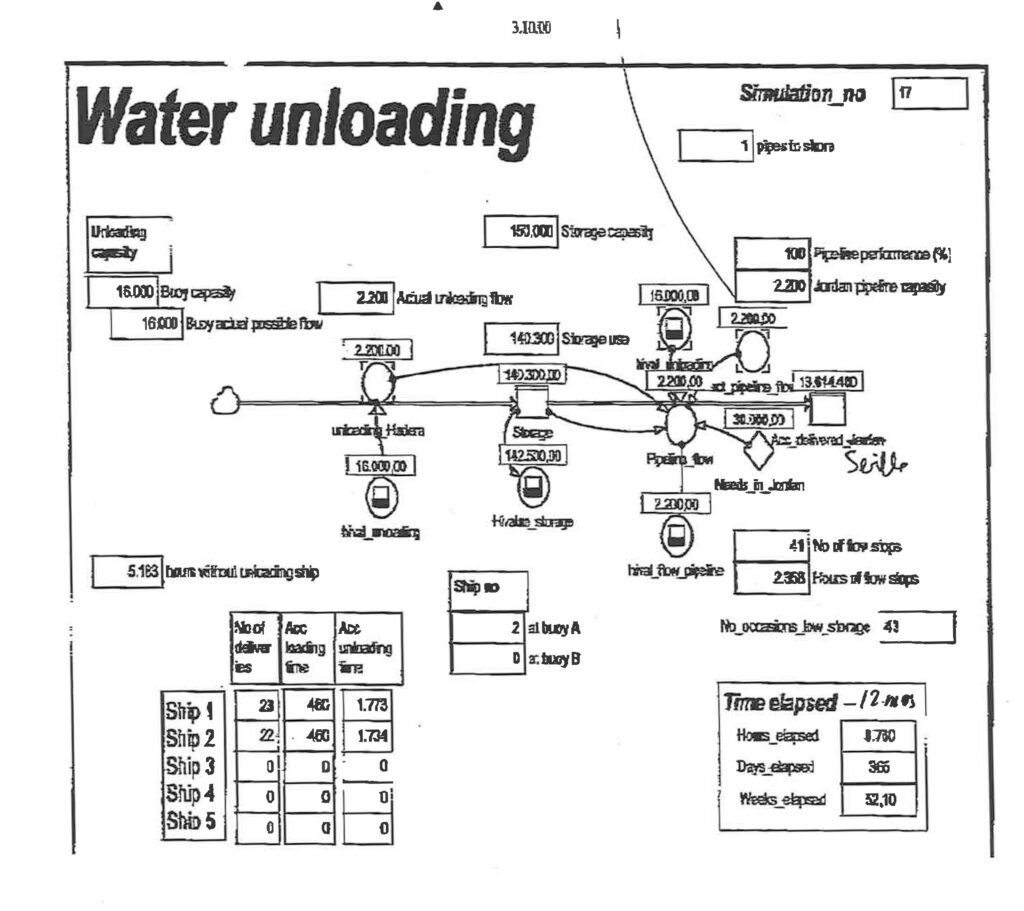

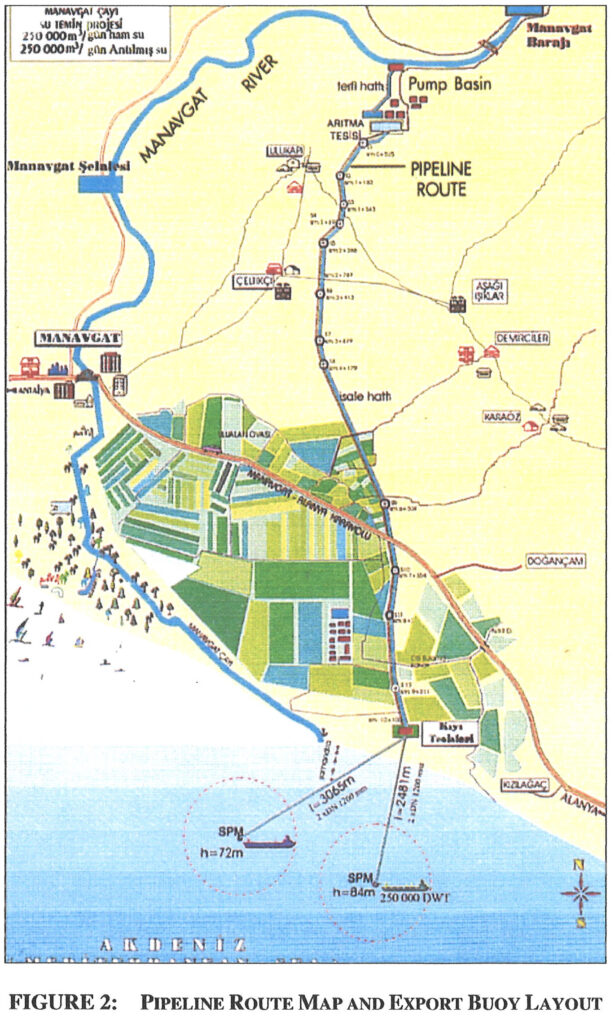

The water is collected from the river Manavgat, that origins from the eastern slopes of the Western Taurus Mountains in Turkey and has an average flow of 147m3/sec, corresponding to some 4,6 billion m3/year. The water treatment plant in Manavgat has a capacity of approx. 180 mill. m3/year, i.e. 2 x 250 000 tons/day to load two Suezmax tanker ships a day from two separate loading buoys.

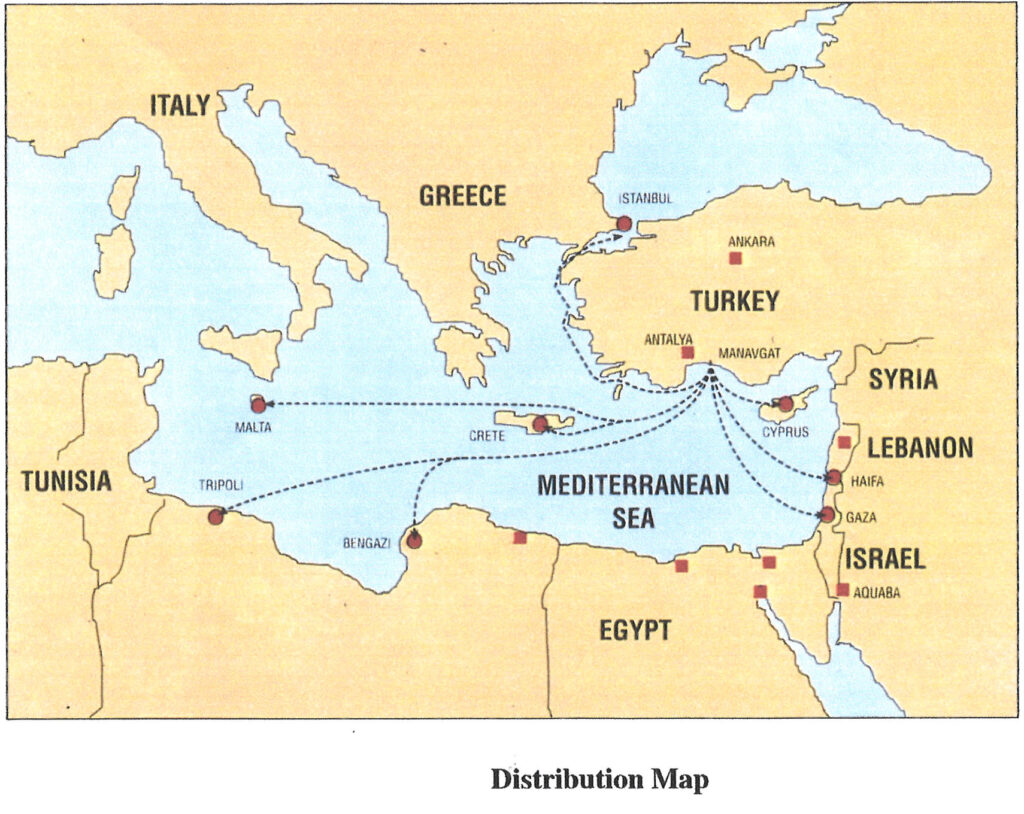

Half of the capacity can be supplied as refined water, and there are two separate pipe lines, each of 10 km length with diameter Ø = 1 600 mm passing by the city of Manavgat to the Mediterranian Sea shore, proceeding to the loading buoys some 2,5 and 3,0 km offshore as shown in (Fig.2, 3 and 4).

The original idea was to offer additional sweet water supplies to countries around the Mediterranian Sea according to the Distriution Map below, and sweet water was supplied, first of all to Cyprus. But the full capacity was never utilized.

Today WTP holds rights to collect sweet water from the plant in Manavgat, and supplies are planned to Saudi Arabia and Pakistan according to exclusive agreements signed. The business partner in Saudi Arabia has a direct link to their Government.

In order to secure future supplies, WTP is looking for sweet water sources and establishing contacts in Greece, Italy and Albania. Sweet water will then be offered to further places according to the original Distribution Map

WTP also has the ability to convert sea water to fresh water “on the go” with the FlexiTank mobile unit

Environmental impact

The Middle East is one of the poorest areas in the world in terms of sweet water, and the countries in the region compensate for it by the use of desalinated water. Some 65% of the global desalination capacity is located in the Arabian Peninsula, and a majority of the plants are distillation plants.

Besides supplying good quality sweet water to people in the area, WTP will bring a substantial contribution to the environment, when delivering ships loads of sweet water. The idea is that, the ships loads are to replace desalinated water, leading to desalination plants being closed.

Shut down of desalination plants contributes to the environment locally by reduced emissions of salt and other chemicals to the sea water, and globally by reduced emissions of CO2 and NOx to the air.

F.inst. will replacement of 100 mill. tons desalinated water per year result in a reduction of 4 mill. tons per year high concentration salt returned to the sea shore, based on 4% salt concentration in the sea water.

A report on “Environmental Aspects of Desalination” presented to a workshop in Dubai already in December 2003 (Fig.6) is highlighting this and listing further chemicals following the same route to the sea shore: “Concentrated brines, backwash liquids containing scales and corrosion salts and antifouling chemicals“. Also an increase of temperature up to 5-6 °C is mentioned, all together killing any life in the coastal area of the desalination plant.

WTP’s contribution to the global environment is reduction of CO2 and NOx to the air.

For the calculation of CO2 emissions to the air there are empirical formulas available, based on the consumption of 30 kilos of oil to evaporate 1 ton of water, and also the burning of 1 ton of oil creating 3,2 tons of CO2.

Due to scaling of the boiler water pipes, the efficiency of the evaporation is with the time reduced to η = 50% or less, at least doubling the consumption of oil.

The calculations based on full capacity operation and supply of 100 mill. tons of water per year are then as follows: 100 mill. tons x 30/1000 x 3,2 x 2 ≈ 19,2 mill. tons reduced CO2 emissions per year to the air.

When removing desalination plants from operation, it is strongly recommended to remove the oldest distillation plants first, because of the scaling inside the steel pipes in the combustion chamber, due to the salty water from outside pumped into the pipes all the time. The scaling causes a considerable reduction of heat transfer from the burning oil to the water, increasing the oil consumption and reducing the efficiency. Finally it might lead to overheating of the pipes causing them to burst.

N-W is supplying spring water of high drinking quality, bottled in cardboard boxes, as mentioned above under “Deliveries to Customers“. The company was registered in Norway 2020-02-19, and deliveries are so far limited to domestic Norwegian customers, aiming however at global expansion.

The cardboard boxes are made with seven different layers to protect the water during storage, and the environmental footprint is limited, since also the cap and its attachment to the box is made from the natural material sugar cane.

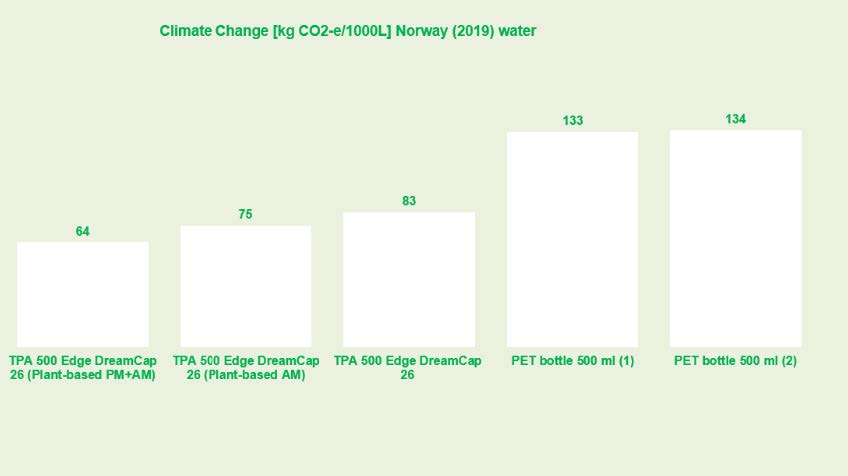

The environmental footprint is referred to in the excerpt from an information pamphlet (Fig.7) from the manufacturer, Tetra Pak, in case the box is burned together with mixed waste.

Impact on customers economy

Desalination is a costly way of providing sweet water. A clear and simple example for calculation purpose is the distillation process, using 30 liters of oil to evaporate one ton of water. 30 liters is 1/5 of a barrel, and when the oil price is USD 50,- a barrel, the cost element just from the oil to be burned, is USD 10,- per m3.

Additional cost elements are f.inst. operation, maintenance, chemicals, spare parts, not to talk about the original investment, when building the plant.

The main cost elements for the reverse osmosis process would be energy and routine replacement of diaphragms, again in addition to the original investment.

It does not take advanced mathematics to see that, purchasing ships loads of sweet water turns out favourable.

In retrospect

The today’s inventor, still going strong, Mr. Viggo H Amundsen, was present and active in contract negotiations about supply and transportation of water from the completed Manavgat sweet water plant to Israel and Gaza in the late 1990s as mentioned under “Sweet Water Sources“ above. The discussions were part of the Oslo agreement, that turned into nothing as some of the World Super Powers backed out, and Israel as well fell out.

Mr. Amundsen’s participation in the discussions fits well in with his membership in the “Turkish Chamber of Shipping“.

A different way of handling transportation of water was the use of bags in different shapes and sizes up to 20 000 m3, made from a very special design coated fabric of the inventor’s own brand, and moved by tugs or helicopters.

The bags turned out to be perfect for oil spill recovery, and in cooperation with the Norwegian ships service company Unitor the inventor sold bags worth hundreds of millions NOK to almost 100 different countries around the globe.

In 1991 the inventor received The World Trade Award for the best oil spill recovery equipment in the world, that was handed over to him by HM Princess Ann in the Guild Hall of London.

In 1992 DuPont presented a detailed description of the Oil Bag, and the same year Voyager presented the first Oil Bag to be delivered to Malaysia.

The bags were acknowledged as military equipment quality, and they were accepted to be military repurchase products. And the inventor is FED DD approved with SBTV Approval Number and FED Trade Ticket Approval. The information was copied to the globally operating big banks and organizations: JFT, FED UK, Interpol Finance Wing, World Bank Humanity Wing, HSBC and Commerzbank.